Everything you need to know about spark plugs

Spark plugs have a tough job to do, always making sure your engine is firing on all cylinders. How do they do it? And which is the right spark plug to choose?

Note: The videos are in German.

- Spark Plug Basics

- Spark plug design

- What does the code on a spark plug actually mean?

- Spark plug numbering system

- What must you remember when changing your spark plug?

- Heat range

- Spark plug appearance: Types of damage normal appearance of a used spark plug

- An intact spark plug

- Deposits

- Insulator breakage

- Melting

- Carbon fouling

- Iridium spark plugs

- Interference suppression

- Electrode gap

- Cleaning the spark plug

- Installation

Spark Plug Basics

No petrol engine is without spark plugs: For your engine, a constant and sufficiently powerful ignition spark is essential for good cold starting, high performance, low emissions and economical fuel consumption.

Depending on the engine speed, a spark plug has to deliver an ignition spark to the engine between 500 and approx. 5,000 times every minute. At the same time, it operates under widely fluctuating thermal loads and large pressure differences – it is therefore one of the wearing parts on a motorcycle that is subjected to extreme stresses, and must be changed at regular intervals, as specified by the manufacturer.

Spark plug design

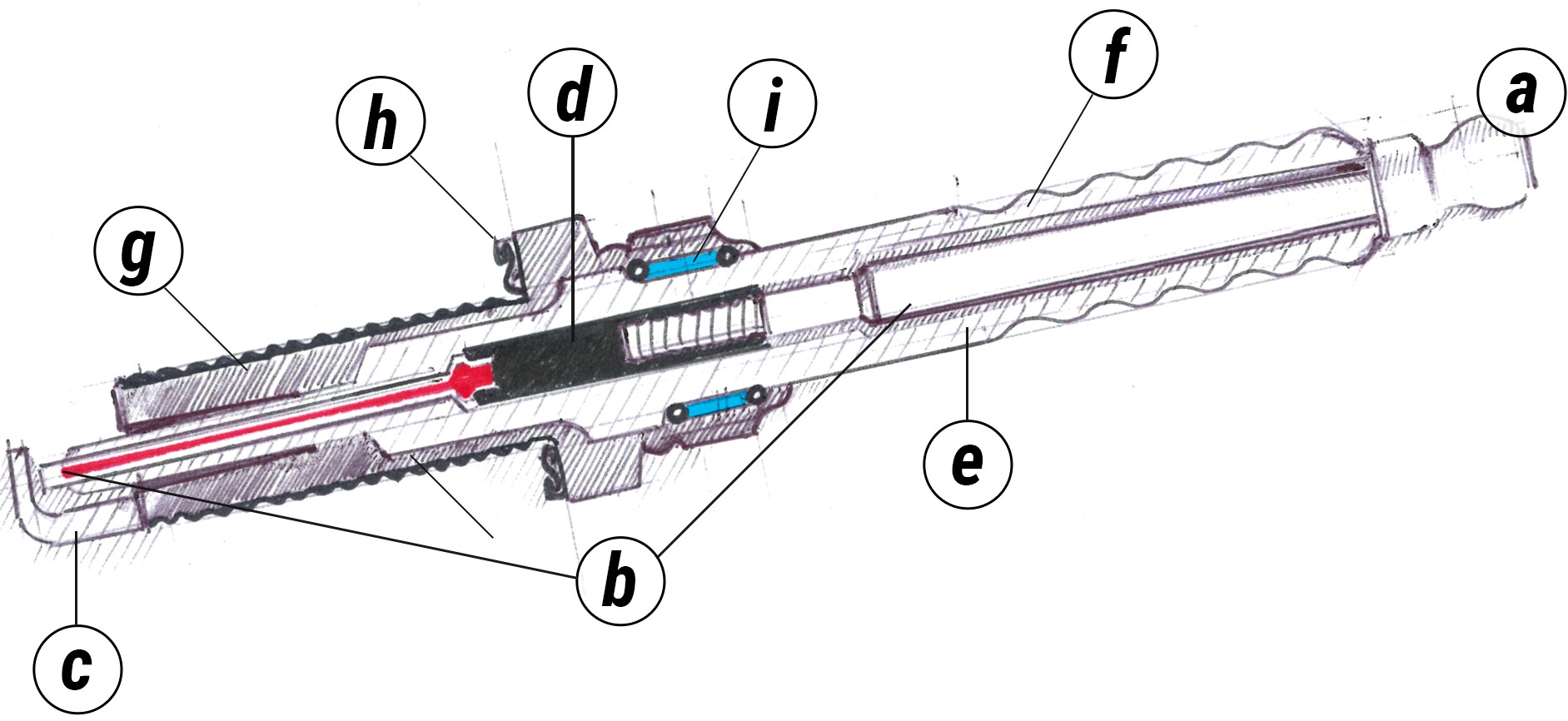

At the top of the spark plug is the terminal (Fig. 1a) for attaching the spark plug connector. Here, the high voltage of the ignition coil from the ignition unit is fed via the thick HT (high tension) lead to the spark plug. The terminal (SAE cap or 4 mm thread) must always be compatible with the spark plug cap used in order to ensure a secure fit!

The centre electrode (Fig. 1 b) conducts the current to the other end of the spark plug, from where it jumps as a spark to the ground electrode (Fig. 1 C), thereby igniting the fuel-air mix in the combustion chamber.

An interference-suppression resistor (Fig. 1 d) in the centre electrode prevents radio frequency interference, or RFI, (e.g. so that the spark plug does not interfere with your radio reception) and, at the same time, protects your motorcycle's sensitive electrical system against electromagnetic pulses. If you use a non-resistor spark plug, then the spark plug cap must have a resistor instead. To ensure that the voltage is only discharged where it should, the centre electrode and resistor are sheathed in a ceramic insulator (Fig. 1 e). The ribbing of this insulator also provides flashover (leakage current) protection (Fig. 1 f) by lengthening the path which stray electrons have to travel.

Fig. 1: a) Terminal; b) Centre electrode; c) Ground electrode; d) Resistor; e) Insulator; f) Flashover protection; g) Metal housing; h) Gasket; i) Inner seals (with talc ring);

The metal housing with its thread (Fig. 1 G) is responsible for ensuring that the spark plug is securely seated in the cylinder head. It also forms the spark plug's ground conductor, and is important for dissipating heat. A gasket provides a gastight connection between combustion chamber and spark plug to prevent the combustion pressure from escaping when heat causes the two parts to expand at different rates. The gasket (Fig. 1 h) also acts as a means of heat exchange. The same function is performed by the inner seals (Fig. 1 i). The only difference is that here the gastight connection is between the insulator and the metal housing.

What does the code on a spark plug actually mean?

On every spark plug you will find a rather cryptic series of letters and numbers. It's important to understand this code so that you know whether a particular spark plug is compatible with your motorcycle. NGK, for example, uses a coding like the one shown here on its spark plugs (see the "Spark plug numbering system" table below).

Spark plug numbering system

The standard type code stamped on spark plugs is given here. In addition, there are some special designations.

What must you remember when changing your spark plug?

If you fit the wrong spark plug in your motorcycle, the engine may misfire or lose performance. It may also cause increased fuel consumption and starting problems. In extreme cases, you could even end up with costly engine damage. So you should always use the spark plug specified for your particular motorcycle model by the motorcycle manufacturer in your owner's manual, service data sheet or workshop manual. You should also consult the spark plug manufacturer's listing. This listing will also show you whether a more sophisticated iridium spark plug is available for your motorcycle.

B | P | R | 5 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread dimensions/hex size | Structure | Interference-suppression resistor | Heat range --- > | |||||||||||

| A | 18 mm / 25.4 | P | Projected insulator type | R | Resistor type | 2 | + | Hot types | ||||||

| B | 14 mm / 20.8 | M | Compact type | Z | Inductive resistor type | 4 | + | |||||||

| C | 10 mm / 16.0 | U | Surface or semi-surface discharge type | 5 | + | |||||||||

| D | 12 mm / 18.0 | 6 | + | |||||||||||

| E | 8 mm / 13.0 | 7 | – | |||||||||||

| AB | 18 mm / 20.8 | 8 | – | |||||||||||

| BC | 14 mm / 16.0 | 9 | – | |||||||||||

| BK | 14 mm / 16.0 | 10 | – | Cold types | ||||||||||

| DC | 12 mm / 16.0 | |||||||||||||

E | S | -11 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Thread reach | Design features | Electrode gap | ||||||||

| E | 19.0 mm | B | Fixed SAE terminal nut (CR8EB) insulator tip | None | Motorcycle: 0.7 – 0.8 mm; car: 0.8 – 0.9 mm | |||||

| EH | 19.0 mm, zur Hälfte ausgeführt | CM | Oblique ground electrode; compact type (insulator length: 18.5 mm) | -8 | 0.8 mm | |||||

| H | 12.7 mm | CS | Oblique ground electrode; compact type (insulator length: 18.5 mm) | -9 | 0.9 mm | |||||

| L | 11.2 mm | G, GV | Racing spark plug | -10 | 1.0 mm | |||||

| F | Kegeldichtsitz | I | Iridium electrode | -11 | 1.1 mm | |||||

| A-F---10.9 mm | IX | Iridium IX spark plug | -13 | 1.3 mm | |||||

| B-F---11.2 mm | J | 2-projecting-electrodes | -14 | 1.4 mm | ||||||

| B-EF--17.5 mm | K | 2-ground-electrodes | -15 | 1.5 mm | ||||||

| BM-F--7.8 mm | -L | Reduced heat range | ||||||||

| None | Kompaktkerze | -LM | Compact type (insulator length: 14.5 mm) | |||||||

| BM---9.5 mm | N | Special ground electrode | -S | Special gasket | ||||||

| BPM--9.5 mm | P | Platinum electrode | -E | Special resistor | ||||||

| CM---9.5 mm | Q | 4-ground-electrodes | ||||||||

| S | Standard type | |||||||||

| T | 3-ground-electrodes | |||||||||

| U | Semi-discharge type | |||||||||

| VX | Platinum spark plug | |||||||||

| Y | V-grooved centre electrode | |||||||||

| Z | Special design | |||||||||

Heat range

A spark plug's heat range defines the thermal behaviour of the spark plug in the engine. If the spark plug is too "cold" for the engine, it will not reach an adequate operating temperature (500°C – 900°C), so it will be prone to carbon fouling, and the electrode or electrode foot will be too dark, even though the fuel mixture is correct. Ignition energy is lost. On the other hand, if the spark plug is too "hot", autoignition (caused by hot spots instead of the spark) may occur, leading to damaged pistons and valves.

The higher the load on the engine, i.e. the hotter it runs, the colder the spark plug needs to be. In contrast, if a slow-running engine generates less heat, then a hotter spark plug is required.

The motorcycle manufacturers endeavour to recommend a spark plug heat range that permits wide all-round use for each motorcycle model. If a motorcycle is mainly used under specific conditions, or if the engine has been modified by tuning, the same type of spark plug but with a different heat range may be more advantageous – but you should be cautious here.

If, for example, a motorcycle is restricted to, or if it is almost exclusively ridden at low speed in town traffic, the spark plug will be constantly fouled with carbon, causing problems when your start the engine. This problem may be cured by using a hotter spark plug (NGK: lower code number), which self-cleans more effectively. But before you try this, you should always check whether the fuel mixture is correct, It could be that the mixture is simply too rich, or something else is not right. It's best to consult a motorcycle workshop before you change the spark plug heat range. Or you could try an iridium spark plug, if one is available for your motorcycle model.

In contrast, if a tuned motorcycle is ridden in a more sporty style, especially on the motorway, and the engine runs hot even though the carburettor is perfectly adjusted, then a colder spark plug (NGK: higher code number) may be the answer. Here too, you should ask a motorcycle workshop.

Fig. 2: An intact spark plug

Spark plug appearance: Types of damage normal appearance of a used spark plug

An intact spark plug

This is how an intact spark plug looks. The whitish-grey discolouration is normal. It comes from fuel additives that are not fully combusted, and is the result of controlled, normal combustion.

Fig. 3: Spark plug with deposits

Deposits

Here you see a spark plug with heavy deposits. These may be caused by, for example, poor fuel quality, high oil consumption in a mechanically worn engine or combustion of coolant due to a damaged cylinder-head gasket. They increase the likelihood of autoignition (the deposits continue to glow).

Fig. 4: Spark plug with broken insulator

Insulator breakage

A broken insulator, as shown in Fig. 4, can lead to engine damage. The breakage is usually caused by using an incorrect tightening torque or if spark plugs are dropped on a hard surface (e.g. your garage floor) before they are fitted.

Fig. 5: Spark plug with melting

Melting

On this spark plug, the centre and ground electrodes have fused together. This happens when the spark plug overheats. In this case, there is a possibility that the piston will also have melted. The cause could be choosing the wrong spark plug (incorrect heat range) or an engine malfunction (knocking or autoignition).

Fig. 6: Spark plug fouled with carbon

Carbon fouling

Carbon build-up occurs if the spark plug is frequently operated at below its self-cleaning temperature (450°C) – if, for example, you only go short distances, or if you choose an incorrect heat range (too cold).

Fig. 7: The thin centre electrode makes an iridium spark plug easy to recognise

Iridium spark plugs

For many motorcycle models, technically superior iridium spark plugs can be used as an alternative to the standard version. They have an iridium alloy on the tip of the centre electrode. Iridium is a noble metal, and one of the hardest metals in the world. It only melts at 2,450°C or above, and is very resistant to spark erosion. For this reason, the life of iridium spark plugs is double that of standard spark plugs! What's more, the noble metal allows the centre electrode, at 0.6 mm, to be much thinner.

This, in turn, considerably reduces the level of ignition voltage required, makes the ignition spark more powerful, and helps to improve the expansion of the flame front in the combustion chamber. So iridium spark plugs not only have a longer life, but also optimise combustion in the engine. The electrodes themselves self-clean more effectively, so the spark is less susceptible to carbon fouling. What this means is improved starting, engine performance, spontaneous throttle response and fuel consumption. Iridium spark plugs are also ideal for classic motorbikes, or if you do a lot of town riding.

Fig. 8: Unsuppressed spark plugs need a cap fitted with an interference-suppression resistor

Interference suppression

Either the spark plug or the cap must have a resistor to prevent the spark from causing radio interference and to protect your motorcycle's electrical system. This is a statutory requirement. On a motorcycle, it is sufficient for the spark plug or cap to be fitted with a 5 kOhm suppression resistor. If the resistance is too high, it will weaken the ignition spark, So it is neither necessary nor advisable to use a suppressed spark plug and suppressed cap together (although most engines would still fire).

Fig. 9: Use a feeler gauge to check that the electrode gap is correct

Electrode gap

The correct gap between ground electrode and centre electrode is decisive for a strong ignition spark. If the gap is not correct, the engine may misfire or your fuel consumption may rise. If the ground electrode is bent in relation to the centre electrode, e.g. because you accidentally dropped the spark plug on the ground, it will not fire. If the gap is too small, the combustion would be poor, and if the gap is too big, the ignition energy required is greater than the ignition system can deliver.

Fig. 10: Clean the spark plug with a brass wire brush

Cleaning the spark plug

As a rule, the gap is between 0.6 and 0.8 mm, depending on the motorcycle model. Gaps of up to 1.1 mm are less common. You will need to check the table provided by the spark plug manufacturer or the information from the motorcycle maker, and then measure the actual gap on the spark plug using a feeler gauge. If the gap is not right, you can bend the electrode very carefully with a small screwdriver or pliers. You should give the spark plug a good clean with a special wire brush before installing it.

Fig. 11: Apply copper or ceramic paste to the spark plug thread before installing

Installation

You should always let the engine cool down before changing the spark plug, to avoid damaging the thread. Pull the cap off the spark plug and examine it first of all for damage and corrosion (change it if necessary). BEFORE unscrewing the spark plug, examine the spark plug recess and remove any dirt (e.g. with a vacuum cleaner). Unscrew and remove the old spark plug using the correct size of spark plug wrench.

It is recommended to lubricate the spark plug thread lightly with copper or ceramic paste (not lubricating grease) before installing it. This will prevent the spark plug from seizing due to overheating, but has the disadvantage that dirt and grains of sand can very easily stick to the thread if you unscrew the spark plug and lie it down. This would result in damage to the thread – so it's important to keep everything very clean when you're doing anything with the spark plugs.

Please note: When screwing in the new spark plug, be careful to keep it straight to avoid cross-threading. Never use force! If the spark plug does not go in easily, unscrew it again and check the thread. If the thread in the cylinder head is damaged, it may be possible to solve the problem by recutting it with a thread-cutting tap. Find out more under Thread Cutting.

Fig. 12: Spark plug threads are easily damaged, so it's best to tighten with a torque wrench

If you do not have a torque wrench, you can follow the old rule of thumb instead: If the spark plug is new, screw it in by hand, and then tighten it carefully by a half-turn with the spark plug wrench so that the gasket seats itself and the spark plug is secure. If you are fitting a used spark plug on which the gasket has already seated itself, you should only tighten by a quarter-turn.

Tip: You should tighten the new spark plug with a torque wrench, taking care to observe the torque specified in the table below (Fig. 12). Find out more under Torque Wrench Basics.

| Cylinder head material | Thread dia. of spark plugs with flat seat (with gasket) | Thread dia. of spark plugs with conical seat | ||||

| 18 mm | 14 mm | 12 mm | 10 mm | 18 mm | 14 mm | |

| Cast-iron head | 35 – 45 Nm | 25 – 35 Nm | 15 – 25 Nm | 10 – 15 Nm | 20 – 30 Nm | 15 – 25 Nm |

| Aluminium head | 35 – 40 Nm | 25 – 30 Nm | 15 – 20 Nm | 10 – 12 Nm | 20 – 30 Nm | 10 – 20 Nm |

The Louis Technical Centre

If you have a technical question about your motorbike, please contact our Technical Centre, where they have endless experience, reference books and contacts.

Please note!

These tips for DIY mechanics contain general recommendations that may not apply to all vehicles or all individual components. As local conditions may vary considerably, we are unable to guarantee the correctness of information in these tips for DIY mechanics.

Thank you for your understanding.